Explain Injection Moulding Process Plastic Injection Machine And Its Functions Ptfe machinery Basic Of Injection Moulding Process Diagram Working Why Choose Injection Moulding Geomiq Injection Molding Process Steps How Are Plastic Parts Produced We ll explain what injection molding is what the injection moldin injectionmolding Learn everything you need to know about injection molding in this video

The term injection moulding encompasses a handful of processes that inject liquid resin into a tool to form plastic parts Here are four common types Thermoplastic injection moulding Thermoplastic injection moulding is the most common type of moulding It injects thermoplastic resin into the mould where the material cools to form the final part Injection Moulding Process is a comprehensive topic that covers the principles applications and challenges of using thermoplastic polymers to create various shapes and products Learn from ScienceDirect Topics how injection moulding works what factors affect its quality and efficiency and what are the latest developments and innovations in this field

Injection Molding Process Steps How Are Plastic Parts Produced Compression Moulding This Resource Is A Diagram Of The Com Flickr Injection Molding Explained Manufacturing Solutions Group Blow Moulding Process And Working Principle Theteche The Basic Plastic Injection Molding Process Injection Molding Texas The Plastic Injection Molding Process Polychem USA What Is Rubber Injection Molding Doovi Plastic Injection Molding Process EAS Change Systems EAS Change Systems M Ch u Nhi t Cho M y p Phun L G T V n V C ch S D ng

Explain Injection Moulding Process

Explain Injection Moulding Process

Explain Injection Moulding Process

http://diyakomashin.ir/Uploads/Public/news/f966a4f477964e3f9ccabb07889bc0a8.jpg

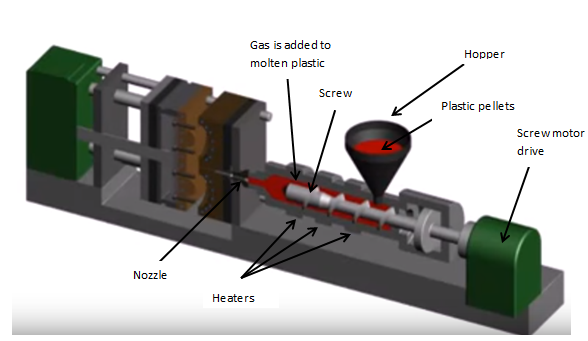

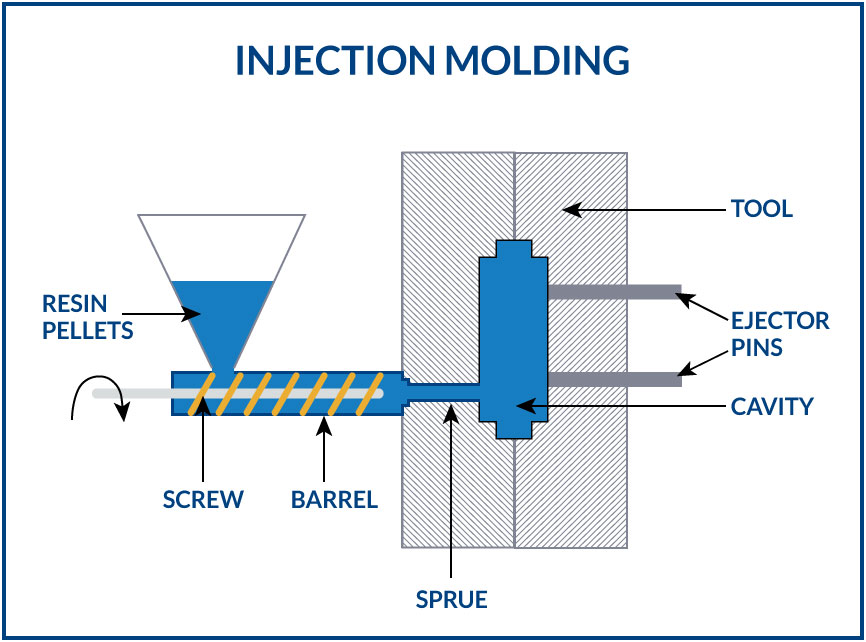

Injection molding is a process in which a thermoplastic polymer is heated above its melting point resulting in the conversion of the solid polymer to a molten fluid with a reasonably low viscosity This melt is mechanically forced i e injected into a mold in the shape of the desired final object The low viscosity of the molten polymer

Templates are pre-designed documents or files that can be utilized for various purposes. They can save time and effort by supplying a ready-made format and design for creating different kinds of content. Templates can be used for individual or professional tasks, such as resumes, invitations, flyers, newsletters, reports, presentations, and more.

Explain Injection Moulding Process

Reinforced Reaction Injection Molding RRIM Closed Molding

Compression Moulding This Resource Is A Diagram Of The Com Flickr

Injection Molding Explained Manufacturing Solutions Group

Blow Moulding Process And Working Principle Theteche

The Plastic Injection Molding Process Polychem USA

What Is Rubber Injection Molding Doovi

Injection moulding is a manufacturing process that allows for parts to be produced in large volumes It works by injecting molten materials into a mould or mold in the United States It is typically used as a mass production process to manufacture thousands of identical items

Injection moulding is a manufacturing process used to produce single parts and products using various materials most commonly thermosetting and thermoplastic polymers

Injection Molding Definition Injection Molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold

Molding is the process of shaping a liquid or flexible raw material using a rigid frame called a mold This process which is very popular today in many industries took off at the height of the Second World War when the need for mass produced products increased The Industrial Rise of Molding Mass Production

Injection molding is a forming process using molds Materials such as synthetic resins plastics are heated and melted and then sent to the mold where they are cooled to form the designed shape Due to the resemblance to the process of injecting fluids using a syringe this process is called injection molding

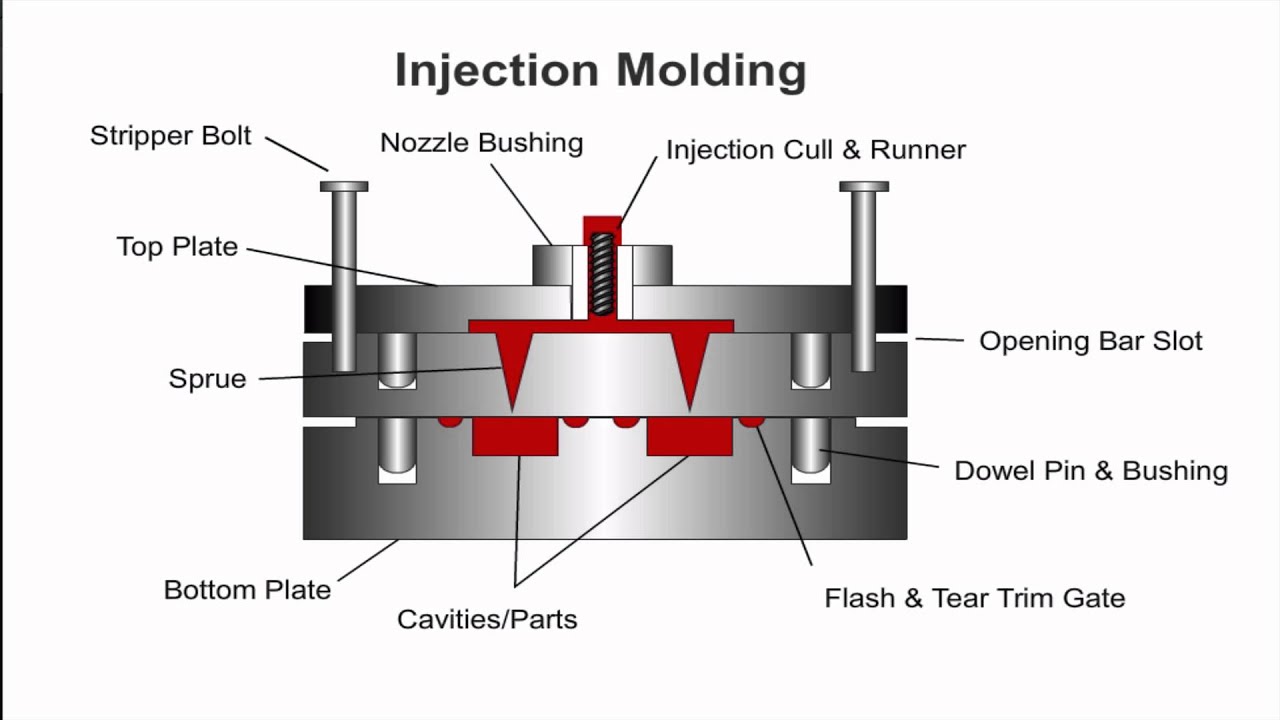

The Injection Molding Process Steps Assuming that the mold has already been created injection molding becomes an easily repeatable process consisting of six discrete steps 1 Clamping The first step of the injection molding process is clamping Injection molds are typically made in two clamshell style pieces The injection moulding process involves melting plastic pellets in a heated barrel injecting the molten plastic into a mold cavity and then cooling it to create a solidified product It s a complex process but the end result is worth it high quality identical parts produced at a rapid pace What is Injection Moulding

Injection moulding is a manufacturing technique that involves the formation of plastic or rubber materials by introducing heated material into a mould Injection moulding is the ideal method of processing when high precision intricate geometries and mass production of plastic parts are required